Waste treatment

Treatment and Utilization of Root, Stem, and Pulp

Solid wastes from cassava starch production are cassava stem, soil, sand, and pulp. There still lacks of an interest in utilization for value adding of these wastes. Nowadays, the wastes are mostly used as soil additive.

1. Pulp

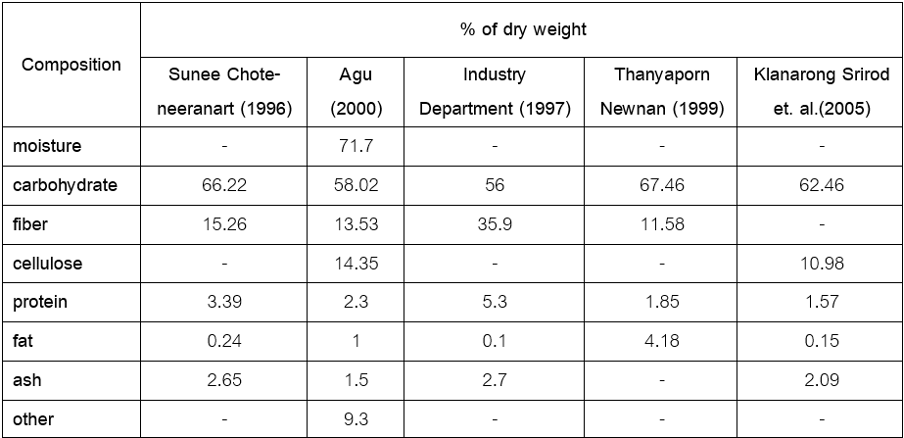

Cassava pulp is the main by-product from the production process. Pulp is fine and white with moisture content up to 75%. Carbohydrate, 55-56%, is the main composition. Starch remaining in the pulp may approximately be 50-60% of its dry weight, in which the starch mostly be trapped inside ligno-cellulose. The pulp also contains pectin, cellulose, and fiber of approximately 10-15%, protein of 1.5-5%, fat of 0.1-4%. Other components are minerals: i.e., Fe2+ of 155 ppm, Mn2+ of 40 ppm, Mg2+ of 1100 ppm, Cu2+ of 4 ppm, and Zn2+ of 21 ppm per kg-dry pulp shown in Table 1 (Lohwongwatana, 2009). The pulp can be utilized in many ways, for example, used in animal feed industry, bio-gas production, and ethanol production.

Chemical composition of pulp

2. Wastewater

Cassava starch industries use a large quantity of water in its production process, generating a high volume of wastewater. Parts of the water quantity are vaporized in the dewatering and drying stage. The properties of wastewater before treating are rich in BOD, COD, solid content and low nitrogen content. The major composition is organic substance. Characteristics of wastewater from the cassava starch production industry are shown in the following table.

Characteristics of wastewater from cassava starch production process

Wastewater treatment can be divided into 3 methods: physical treatment, chemical treatment, and biological treatment. Biological treatment is suitable for treating wastewater from cassava starch production, since the characteristic of the wastewater from this industry is rich with the organic substances which are the energy source for the microorganism. Bacteria dealing in the biological treatment can be subjected into 2 major groups: autotrophic bacteria and heterotrophic bacteria.

- Autotrophic bacteria consume free oxygen for metabolizing inorganic compound to produce energy, such as nitrifying bacteria use carbon dioxide (CO2) for changing the ammonium (NH4+) to nitrate (NO3-) .

- Heterotrophic bacteria consume organic compound to obtain energy and carbon. These bacteria can be divided into 3 types:

- Aerobic bacteria are bacteria that can grow and live in the presence of oxygen.

- Facultative bacteria are bacteria that can grow with or without oxygen, which rapidly grow in the oxygen condition.

- Anaerobic bacteria do not require oxygen for growth.

Biological Wastewater Treatment

Biological wastewater treatment can be divided into 2 types: aerobic and anaerobic treatment

1. Aerobic Wastewater Treatment

Aerobic wastewater treatment is a biological process in which free oxygen is supplied for the microorganisms that can grow and alive in the oxygen presence environment. Aerobic bacteria decompose organic compounds in wastewater and change them to ammonium (NH4+), nitrate (NO3-), sulfate (SO42-) , and phosphate (PO43-) . The advantages of the aerobic process are odor reduction and it can reduce organic compound until the treated water meets the discharge standard. However, its disadvantages include this system requires the large area, high operating cost for the aeration for the microorganism, and the final product cannot be useful. The aerobic treatment systems are stabilization pond, aerated lagoon, activated sludge, trickling filter, rotating biological contactor; RBC, and construction wetland.

2. Anaerobic Wastewater Treatment

Anaerobic treatment is the wastewater treatment system without the need of oxygen, since microorganisms are anaerobic type. Its advantages are less energy requirement with biogas as the final product and less sludge produced. Biogas can be used for thermal or electricity generation. . Disadvantages are long start-up. Additionally, the value of chemical oxygen demand (COD) after treatment is higher than standard. Post treatment such as open ponds is required. The anaerobic treatment systems are anaerobic pond, septic tank, anaerobic filter, upflow anaerobic sludge blanket (UASB), anaerobic fixed film, etc.

Types of Wastewater Treatment System

Open Pond

The cassava starch production industry is an agro-industry, producing the high strength wastewater. In the past, the widely used traditional treatment system is an open pond system. Wastewater flows through a series of open ponds until the treated wastewater meets the standard requirement. As the treatment efficiency is low, it requires a large land area. An open pond system consists of the anaerobic ponds, facultative ponds, and aerobic ponds respectively connected. This system eliminates organic compounds within wastewater by the activities of microorganism. Nowadays, the wastewater treatment system for cassava starch industries consists of anaerobic ponds, facultative ponds, and aerobic pond, respectively.

1. Anaerobic Ponds

An anaerobic pond is large in its size, and its deep can be as deep as 3.0-4.0 meter. This system can support wastewater with high organic loading rate (OLR) or high biochemical oxygen demand (BOD). The pond needs to be deep and small in its surface area. This geometry simultaneously with the high OLR is fed yield the photosynthesis cannot be occurred, condition inside the pond then becomes anaerobic. During wastewater travelling in the pond, organic compounds are degraded anaerobically, which usually turns sulfate component in wastewater to odorous compound such as hydrogen sulfide and another sulfide associated compound. Some compositions of wastewater become several kinds of the gas, but most of them are methane and carbon dioxide. Wastewater entered the pond at the bottom to have more opportunity to be consumed by the microbial sludge. The wastewater after treating simultaneously with some amount of sludge leave the pond at the outlet pipe which stays at the opposite site to the inlet but its height is higher, this outlet pipe at the upper zone of the pond have to be installed under the scum level. The anaerobic treatment produces a large volume of the gas, enhancing the mixing inside system.

2. Facultative Ponds

The depth of facultative pond is less than anaerobic pond (which approximately 1.0-2.5 m depth). Microbial activity inside the system consists of 3 zones: upper zone is the symbiosis part between the aerobic bacteria and algae. The bottom zone is the oxygen-free area which suitable for the anaerobic bacterial activity to decompose the organic compounds. The third is the interface zone, this zone contains with the facultative bacteria that can grow with or without oxygen.

3. Aerobic Ponds

An aerobic pond has a wide surface area but the depth is lower than the other. Its depth can be shallow as much as 1.0-1.5 m. The microbes in the system are bacteria and algae which living as symbiosisly. Bacteria decompose organic carbon and then produce CO2. CO2 is then consumed by algae in photosynthesis. This mechanism produces O2, which is used by the aerobic bacteria as the cycle. The shallowness of the pond is suitable for oxygen to infiltrate into the wastewater, and the algae can photosynthesize sufficiently. The pond immediately environment must not be growing by the big tree or must be lacking of the barrier which can hide the wind and the sunlight.

Close System

1. Completely Stirred Tank Reactor (CSTR)

The closed anaerobic tank system is the anaerobic wastewater treatment system. The scrapper is installed at the bottom of reactor that for increase the treatment efficiency. The prominent point of this reactor is the continuous mixing inside the reactor enhances the microorganism to meet their substrates thoroughly. Biogas production efficiency is then increased. This reactor is suitable for the wastewater containing with the high value of suspended solid, which is decomposed by the microbial and produce biogas as the end product (Teeraphon Wattanakoson, 2005).

2. Anaerobic Baffled Reactor (ABR)

One main characteristic of this system is that it contains several baffles installed inside the long reactor. Wastewater is oscillated move upward and downward (or it can be left-right oscillation) follows the baffle installation. This configuration provides more intimate contact between anaerobic bacteria and wastewater inside the reactor until COD is decreased leaving the system.

3. Upflow Anaerobic Sludge Blanket (UASB)

Upflow anaerobic sludge blanket (UASB) uses an anaerobic sludge granular, 1-2 mm of diameter, which have a high sedimentation velocity, to treat the wastewater. The wastewater containing organic compounds flows upward through the granular sludge bed, which make the microorganisms in the sludge contact with organic substances. The treatment process can be divided into 2 layers: the top layer of reactor (water phase) and the sludge bed zone, which is the lower layer. A three phase separator is installed for separating treated waster, gas, and sludge granules. Since, the granular sludge disperses throughout the system without the inert media for attachment, so it safes the cost for these material. This system is suitable for wastewater that contain low suspended solid.

4. Anaerobic Fixed Film Reactor (AFFR)

An anaerobic fixed film reactor (AFFR) is designed to have the reactor packed with the supporting medias, such as nylon fiber, nylon net. The media acts as an attachment surface for the consortia of bacteria to grow as biofilm. This system is high treatment efficiency, since the growth of microbes as biofilm prevents the washout of biomass and enhances the performance and stability of the system. The fixed-film reactors are ideally suitable for treating high-strength wastewater, since it is tolerant to the shock-load. (Pilot plant development and training institute, 1999).