Starch Production

NATIVE STARCH

Cassava starch or tapioca starch, a product extracted from fresh roots is one of the major commercial starches in the global market. It is ranked as the second, after corn starch. The technology of starch production has been greatly improved from low quality starch produced by sedimentation process to high quality starch produced by fully automated and mechanized, dewatering centrifugal process. In this process, roots are transported to factories. Since the roots quickly undergo deterioration due to microbial attack, most starch factories apply good practices to process delivered roots within 1-2 days and avoid the storage of perishable fresh roots.

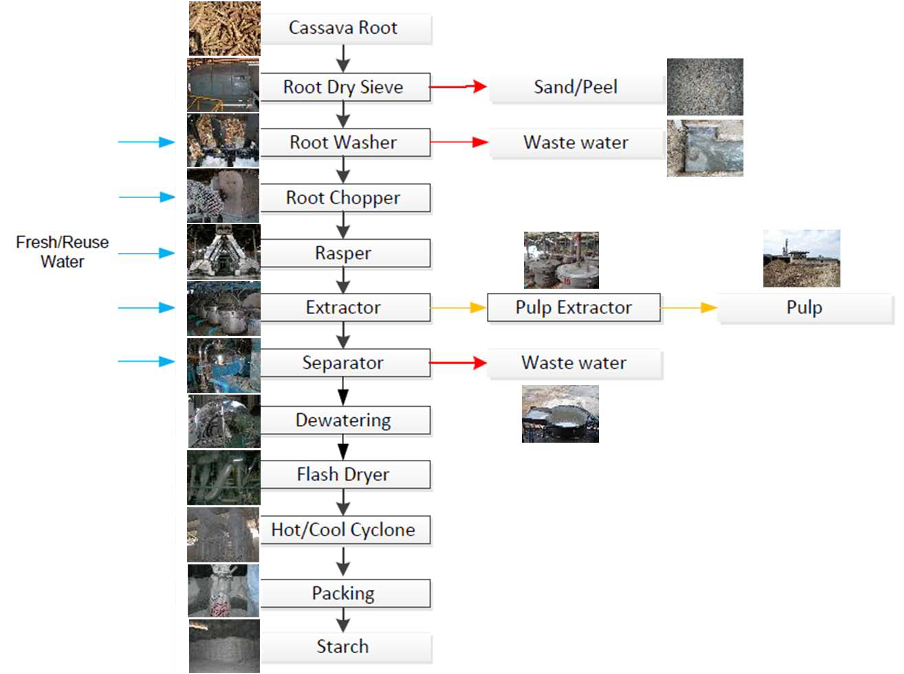

Processed roots are firstly passed through a drum to remove soil, sand, pieces of peels and impurities. Roots are then passed through the root washer and part of the remaining peels, called wet peels, with some hard stems or stumps are manually removed. Washed roots are subsequently chopped and ground by a rasper. Fresh root slurry from the rasper is passed through a series of extractors, from coarse to fine, where the pulp is separated from starch slurry. Starch slurry received from the fine extraction is concentrated from 10 to 17°Be′ to 18 to 20°Be′ or Baume, a measure of the degree of starch concentration. Water is further separated by subjecting the starch slurry to a dewatering centrifuge where the water content is reduced from 60% in slurry to 35-40% in cake. Starch cake is then dried by a pneumatic conveying dryer, known as a flash dryer, to yield the product with 12% moisture content.

A modern cassava starch factory now employs a near zero or zero-waste process wherein the wastewater is used for the production of biogas. This alternative energy can cover 100% of the factory’s thermal energy requirement. The surplus gas can also be converted to electricity.

Cassava starch manufacturing process. Source: Breuninger et al. (2009)

Current cassava starch production process

1. Cassava root receiving

The cassava root was transported via the truck and weighted.The price of cassava root depends on the starch content measured by a norman scale using specific gravity principle. Normally, the roots are stored in the reception yard on a concrete floor before sending to a process line.

2. Cassava root preparing and washing

The cassava roots are sent to seiver to remove soil and sand and then transferred to washing machine for cleaning the roots and separating peels.

3. Rasping

After washing step, cleaned cassava roots are sent to chopper for reducing root size into smaller pieces of approximately 1-2 inches. Small roots are fed to a rasper to further reduce root size to increase cassava starch extraction efficiency.

4. Extraction

The starch slurry that consists of water, starch granules and pulps are pumped to extractors for separating starch granules from pulps (cellulose). Generally, there are 3 extraction units in a plant whereas 4 units in series in larger ones. Extraction can be divided into 2 steps: coarse extraction (with screen size of 60-80 mesh) and fine extraction (with screen size of 90 mesh). During the extraction process, sulfur dioxide acid solution is added to inhibit microbial growth. The discharged cassava pulps contain a significant proportion of starch and moisture. Pulps are sent to the pulp extractors to extract the remaining starch and to reduce moisture using screw press before sun dried. The dried pulps can be sold as animal feed or for cassava chips or pellet production.

5. Separation

The time of cassava starch production process is short to prevent chemical and bio-chemical reactions from microorganism. The separation unit is a continuous process with no storage tank requirement. The centrifugal separators or hydrocyclones are used for this unit. Generally, there are 2 units of centrifugal separators in a factory to separate cassava pulp and other impurities and to increase starch concentration. The added water for this unit is fresh water or sulfur dioxide acid solution.

6. Drying and Packing

After the separation unit, wet cassava starch is dried by a pneumatic conveying dryer which contains a hot air of 200°C. Cassava starch is flown along a dryer tube by hot air and then collected by a cyclone separator. There is usually a short retention time during starch drying step to prevent particle accumulation and emission. The hot air is produced by hot oil burning and filtered before passing through dryer. The cassava starch from cyclone is dry, fine and still hot. It is cooled immediately using a cooling cyclone. The dried starch is then sifted through a sieve to control starch particle size before storage. Small-scale factories use semi-automatic starch packing while the large-scale plants require automatic system.

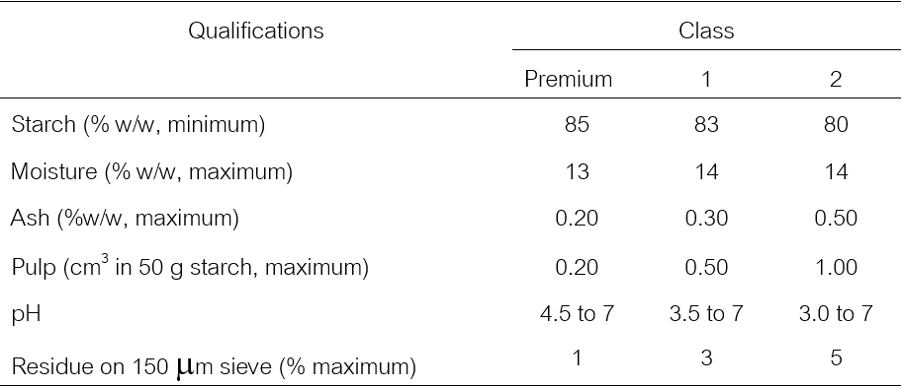

Standard Quality of Thai Cassava Starch

Source: Ministry of Commerce (2006)